Aircraft Interiors Expo (AIX) will return to the Hamburg Messe from 28-30 May 2024,showcasing cutting-edge advances in aircraft cabin systems, In-Flight Entertainment and Connectivity (IFEC), sustainable cabins and more.

Next year’s edition will shine a light on the latest trends and serve as the global platform dedicated to transforming the passenger experience and creating the cabin of the future.

Last year’s event attracted a myriad of airlines, designers, engineers, specifiers, and manufacturers, with visitor attendance increasing by almost two thirds (59%) on the previous year. Plans for the 2024 show are well underway, with AIX set to provide the industry with a chance to identify pioneering solutions, network with industry colleagues, and understand how accessibility and sustainability will impact aircraft interiors in the short and long term.

Transforming the skies

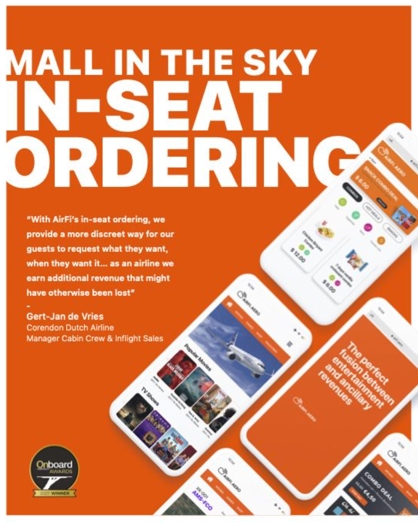

As airlines, OEMs, suppliers, and designers gear-up for modernisation strategies, AIX will provide a platform to discover the technologies, services, and hardware that can enhance every aspect of the cabin. From seating, galley equipment, lighting, and LEDs, to cabin management systems, IFEC hardware, and communications, the event will enable attendees to collaborate and find practical and innovative solutions from more than 400 suppliers.

Returning to the show floor in 2024 will be all the major industry players, including Boeing, Airbus, Recaro, Safran, Panasonic Avionics, and Collins Aerospace — reaffirming the event’s position as the world’s leading marketplace for airlines and the supply chain to meet. Complementing the major OEMs and suppliers, the show will also welcome companies exhibiting at the show for the first time: Comi Aerospace, LXM Aero GmbH, PETER-LACKE GmbH, and Skytec Aerospace will be among those presenting their solutions and services at AIX.

Redefining the onboard experience

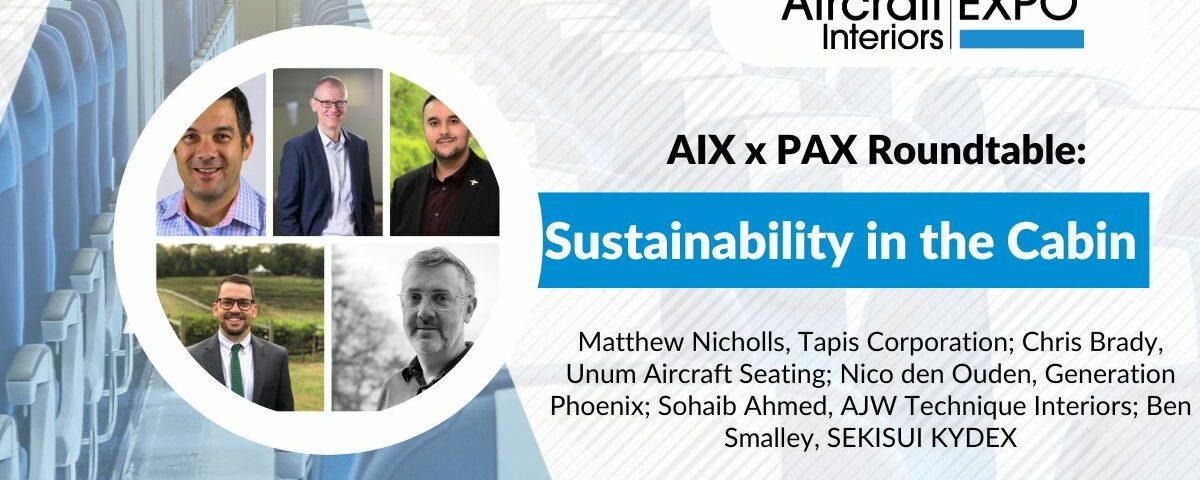

Taking place on the day before AIX opens its doors (27 May), the Passenger Experience Conference (PEC) will return to the Hamburg Messe in 2024, once again featuring an impressive roster of high-profile experts from across a range of sectors. The eagerly anticipated all-day conference provides an unparalleled platform for professionals, airlines, and the global supply chain to come together and immerse themselves in some of the most pressing issues and trends facing the passenger experience sector.

From cutting-edge technologies to revolutionary design concepts, and focusses on core themes including accessibility, diversity, and sustainability, PEC’s speakers will explain the transformative advancements that promise to redefine the passenger experience. Delegates will also have the opportunity to delve into the trends and topics that will determine their future strategies through a series of talks and sessions from keynote speakers and guests.

The ultimate meeting place

Not only will AIX and PEC provide attendees with the chance to learn about the trends shaping the cabin of tomorrow and explore the latest innovations, but they also act as industry meeting points and facilitate unrivalled collaboration and networking. Following the final session of PEC on Monday evening, attendees will be able to connect and unwind at the Welcome Party. Promising an atmosphere of collaboration and celebration, visitors can make new contacts and strengthen existing relationships in an informal setting, ahead of AIX commencing on Tuesday, 28 May.

Attendees to the event can also use the intuitive AIX Connect tool to proactively book meetings with relevant contacts ahead of the event. Its search function enables visitors and exhibitors to discover new contacts, helping them prepare and book meetings before even setting foot in Hamburg.

Polly Magraw, Event Director of Aircraft Interiors Expo, said:

“The industry’s unwavering support has continued to propel AIX forward. As we gear up for the 2024 edition, this year’s show will take cabin concepts to new heights, showcasing a compelling line-up of speakers and sessions that provide solutions for every aspect of the cabin interiors sector.

We look forward to bringing together experts and visionaries from airlines, OEMs, suppliers, and designers to discuss the future of the passenger experience.”

Passenger Experience Conference (PEC), Aircraft Interiors Expo (AIX) and World Travel Catering & Onboard Services Expo (WTCE) return to Hamburg Messe from 28-30 May 2024. Together, all three events provide airlines, lessors, and business jet operators with a unique opportunity to transform onboard environments, address consumer expectations, and deliver exceptional travel experiences.

Visitor registration will open in February 2024. To register your interest to attend, visit the website: